Matalco’s plants operate using lean manufacturing and straight-line metal flow processes, receiving raw materials at one end and shipping out high quality slab and billet at the other end. The scrap is received, segregated, and stored until used. Depending on the alloy being produced, a combination of scrap, primary aluminum, and hardeners are charged into the melting furnaces.

Two facilities have high-capacity chip processing systems allowing for an effective handling and melting process with high recoveries. Energy recovery systems are employed by reheating combustion air to lower costs and reduce emissions. Matalco welcomes toll converting from extruders and rolling mills as well as offers sales of additional quantities of billet and slab to meet your total needs.

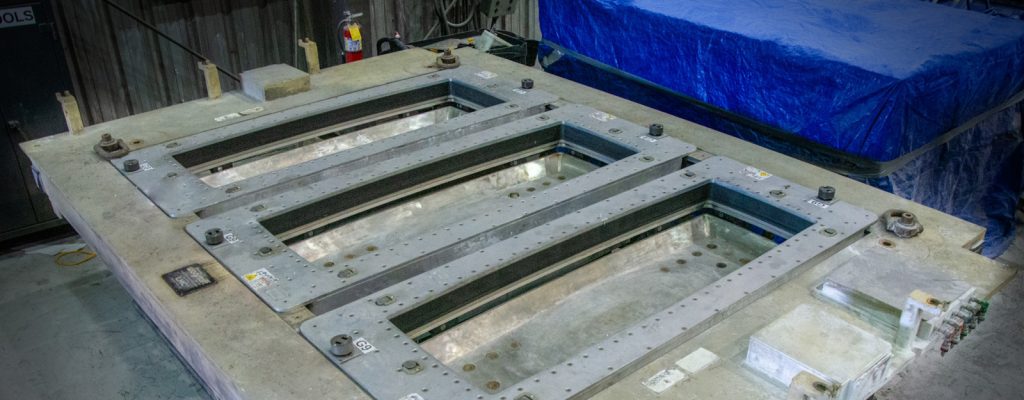

Once the required chemistry target is achieved, any dross is removed and the molten metal is transferred from the melting furnace into a holding/casting furnace. There the molten aluminum bath is stabilized and held until it is ready to be cast, at which point, the liquid metal is released into a trough where it is grain refined, degassed, and filtered prior to being cast.

The finished cast logs are placed on a feed conveyor system or charge cars, which transports the logs automatically into a continuous-homogenizing furnace or batch furnaces, depending on the cast house. Once cooled, the log integrity is tested using ultrasonic and/or eddy-current testing equipment. The logs are then cut to customer specifications, which is marked, packaged, and labeled. Finally, the product is loaded onto trailers for shipping to customers. From the casting pit to finished product, the process is fully automated, only handled when ready to load onto trailers.